MIL-DTL-24749B(SH)

NOTES:

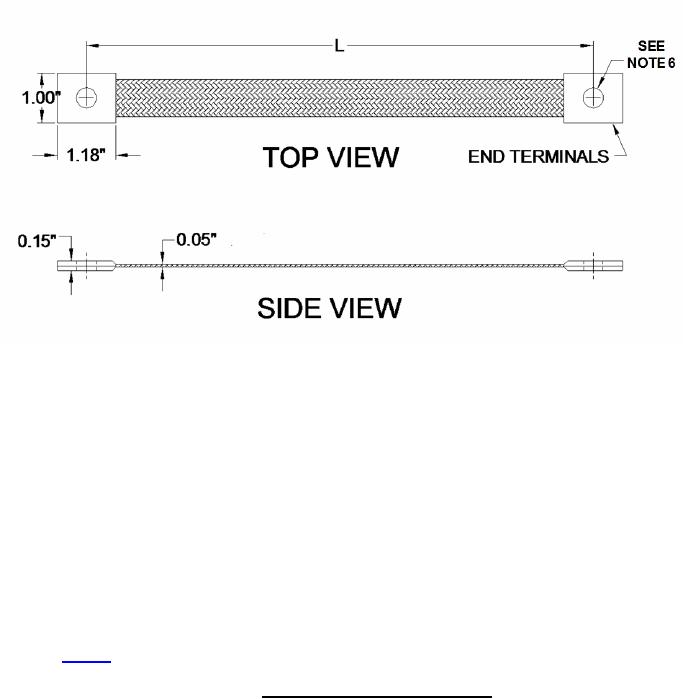

1.

End terminals shall be formed from CRES 316L welded wall tube of 0.625-inch O.D. and wall thickness of

0.065 inch ±10 percent, as specified in ASTM A269 cut to 1.18±0.02 inch length.

2.

The flat end of the braid shall be placed completely into the pipe end.

3.

The pipe shall be compressed to 0.15±0.01 inch to hold fast the braid.

4.

End terminal width when compressed shall be 1.00 inch ±5 percent.

5.

Drill or punch 13/32 inch (0.406) ±0.001-inch hole in each lug after end terminal installation to facilitate 3/8-inch

6.

bolts (for Size Code A-C), or 9/32 inch (0.282) ±0.001 inch-hole in each lug to facilitate ¼-inch bolts (for Size

Code D-F).

See table III for Type IV bond strap standard sizes.

7.

FIGURE 4. Type IV bond strap fabrication details.

16

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business